™

Soil Stabilization of Oklahoma, Inc.

™

Soil Stabilization of Oklahoma, Inc.

™

™

Your source for Green solutions for

foundation and roadbed stabilization, clay soil improvement for plant growth,

plant propagation, and land reclamation from toxic wastes

Engineers and Architects

Structural Engineers, Geotechnical Engineers and Architects are well aware of the problems and costs associated with building on clay soils. They know that standard foundation designs commonly used for light commercial and home construction cannot withstand the effects of clay soil expansion and contraction.

However, there are important facts for engineers and architects to understand about clay soil improvement with Condor SS. Much information is contained in the pages on the Builders portion of this website. However there are other technical aspects of Condor SS that are most likely more beneficial to geotechnical and structural engineers. Those areas will be discussed on this page.

The standard ASTM test methods for one-dimensional swell do not normally reveal the full swell modification characteristics of Condor SS. Swell tests conducted using undisturbed or minimally disturbed soil samples over multi-cycle wet-dry cycles is the only method that will reveal the swell reduction characteristics of Condor SS. This is true even if the soil samples are pre-treated with Condor SS prior to subjection to the swell test. One cycle, ASTM tests will never reveal this effect.

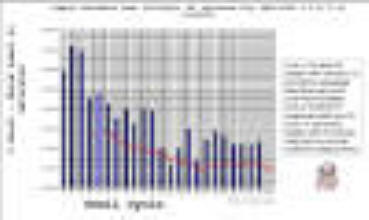

Proof can be seen in the initial swell results and first swells after treatment in the plot below. This home was only 2-years old and had 1/4" longitudinal cracks in sheetrock in the center of the home and numerous smaller cracks elsewhere. Several years after treatment, cracking had not returned.

Actual test results from a home

in Stillwater, OK

Note: Testing using multiple undisturbed swell cycles

Soil Stabilization of Oklahoma has performed long term testing on numerous soil samples using multi-cycle methods. The results are shown above from one typical test using a single undisturbed soil sample of dense clay (CH). During the testing, the water or Condor SS solution was added into the oedometer by inundation using the standard ASTM procedures. The difference between our testing and the standard ASTM method is that the soil sample was taken from a suboptimal moisture condition, almost desiccated, to a saturated state. The sample was then allowed to slowly dry over a minimum of 24-hrs using our proven method of accelerated drying. After drying a new swell cycle was started. This method was documented extremely well in a civil engineering paper. The paper demonstrated the fact that multi-cycle, full shrink to full swell, tests can eliminate the variability in tests results due to varying compaction and loading of the sample. They also showed as others have that accelerated drying can allow many cycles to be run over a few days. They conclusively proved that after about 4-5 cycles from full shrink to full swell the cycles will stabilize to a true swell. The paper also explained some of the variability between the first and second swell cycles and that it is very common for the second swell cycle to be greater than the firs. Our own multi-cycle test methods are what our company uses to determine initial and final swells after treatment for a given site. We can run a full battery of tests, untreated and treated, in less than two weeks of testing. Our tests allow us to provide guarantees to our customers of what they can expect from Condor SS treatment.

A treatment cycle consisted of adding the Condor SS mix solution into the oedometer chamber in order to test the migration characteristics of the product into the soil. Many times very heavy clay samples will require multiple treatments because the first treatment has the effect of opening up the hard clay so that the hydraulic conductivity is increased. Thus the second treatment will show improved effects.

Even though the Condor SS solution was added indirectly into the sample above, one will note after the first treatment cycle, cycle 4, that the first subsequent cycle 5 had a swell slightly higher. This is a fairly typical observation possibly due to opening up the tight clay structure. Subsequent to the initial swell however, the cyclic 6 swell was on its way to reduction. Due to the density of the clay however, the full effects of the Condor SS treatment would not be realized without a second treatment. One of the characteristics of Condor SS is that it will cause the hydraulic conductivity to increase. The first indirect treatment of Condor SS thus essentially opened the structure of the dense clay to allow the second treatment to take effect.

The initial and final swell was even more dramatic the second time the SS solution was added to the soil. As an experiment with this soil sample, electro-osmosis was used as a transport mechanism. After the second treatment the clay sample's cyclic swell/shrinkage profile diminished to a point where the soil could be classified as non-expansive. This type of reduction to 2% or less is typical of all of our soils treated. The red line in the plot is merely a moving average over 10 cycles. The red curve would be the swell change one might expect in normal soil at depth where the moisture does not vary as dramatically. You should also note the variability of the swell cycles after the second treatment. Stabile swell cycles were not seen for several more cycles.

Our accelerated multi-cycle testing has always demonstrated the same results. Our overall conclusion is that the consolidation and swell reduction effects of Condor SS will not realized overnight as it will take time for the treated clay particles to realign to a minimal volumetric configuration and maximum density and for the ionic transport to take place. It should also be apparent, that one-shot standard ASTM testing methods will not demonstrate the ultimate effectiveness of this product in reducing swell to a minimum.

Condor SS has the proven ability to take even the most expansive soils and reduce the swell to 2% or less thus eliminating concerns for swell induced heave.

Contact Information